Customized Inventory Management System for Streamlined Logistics

Customized an inventory management system helps client manage and consolidate cargoes from multiple factories, and ship them with easy

Why We Developed This System

This client is a logistics company based in Ecuador that serves local customers placing orders with factories in China. Once production is complete, the factories send goods to our warehouse.

With the number of collaborating factories continuously growing, we now process 40-60 batches of goods per month. Communication became a challenge, as the client had to coordinate separately with both local customers and multiple factories. To address these inefficiencies, we lauched a customized inventory management system on May 2, 2024 to streamline operations and improve overall coordination.

Website Features

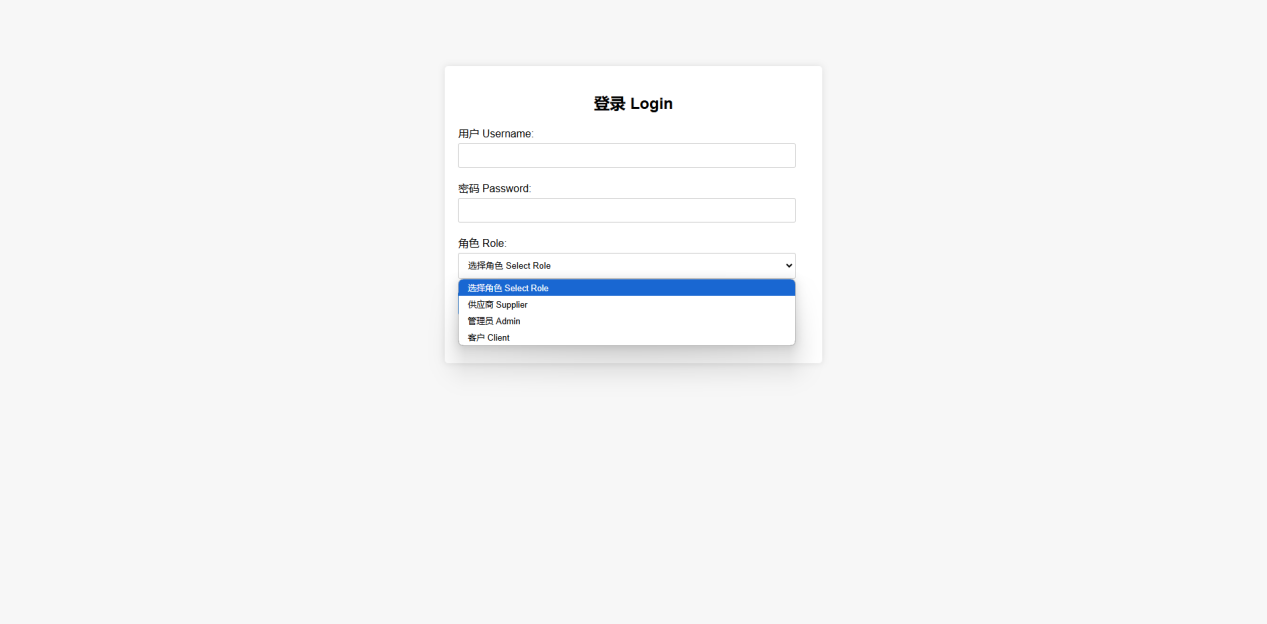

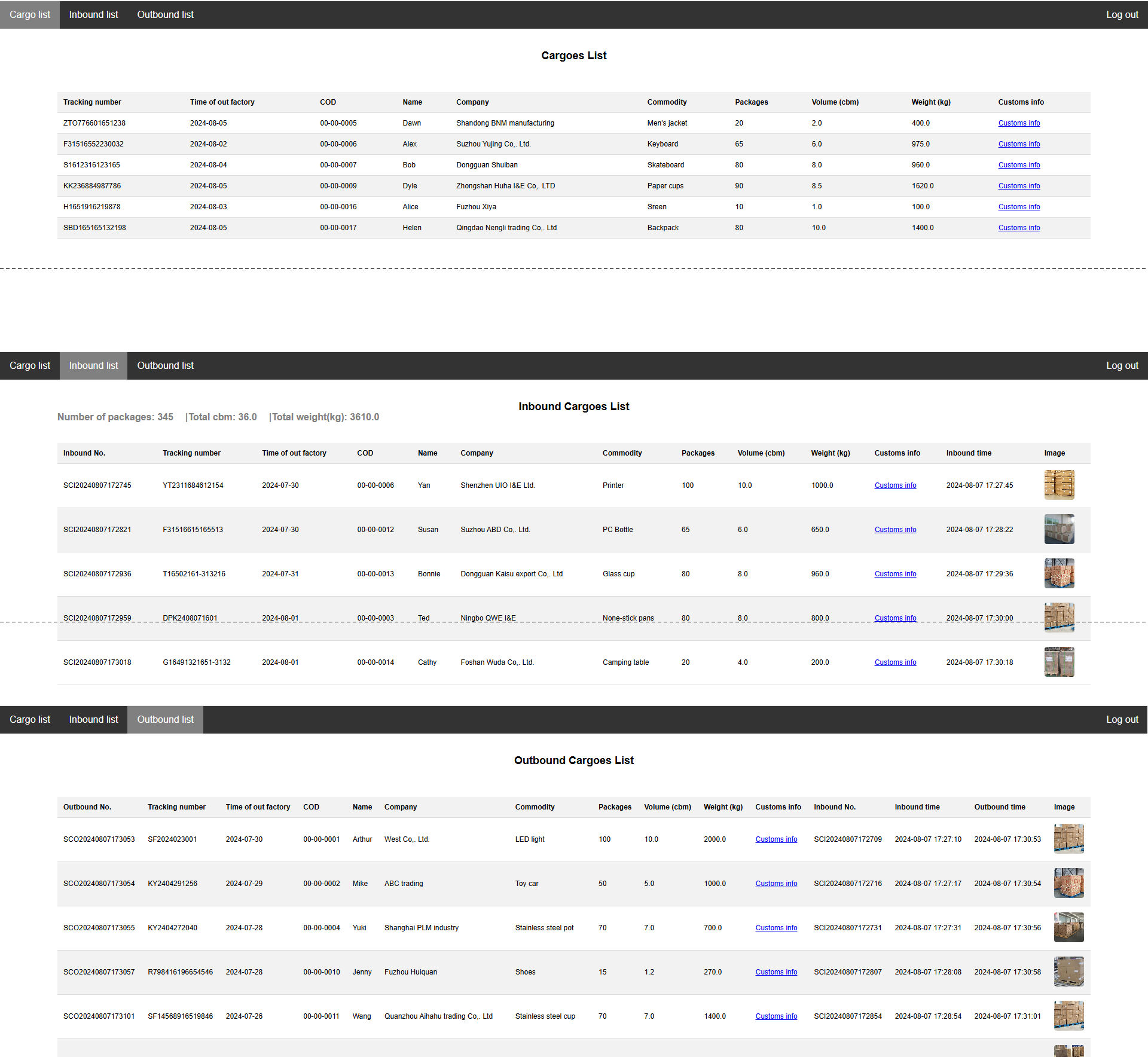

Role-Based Login:

- Supplier Login: Factories can upload cargo details securely, with no access to others' records, ensuring confidentiality.

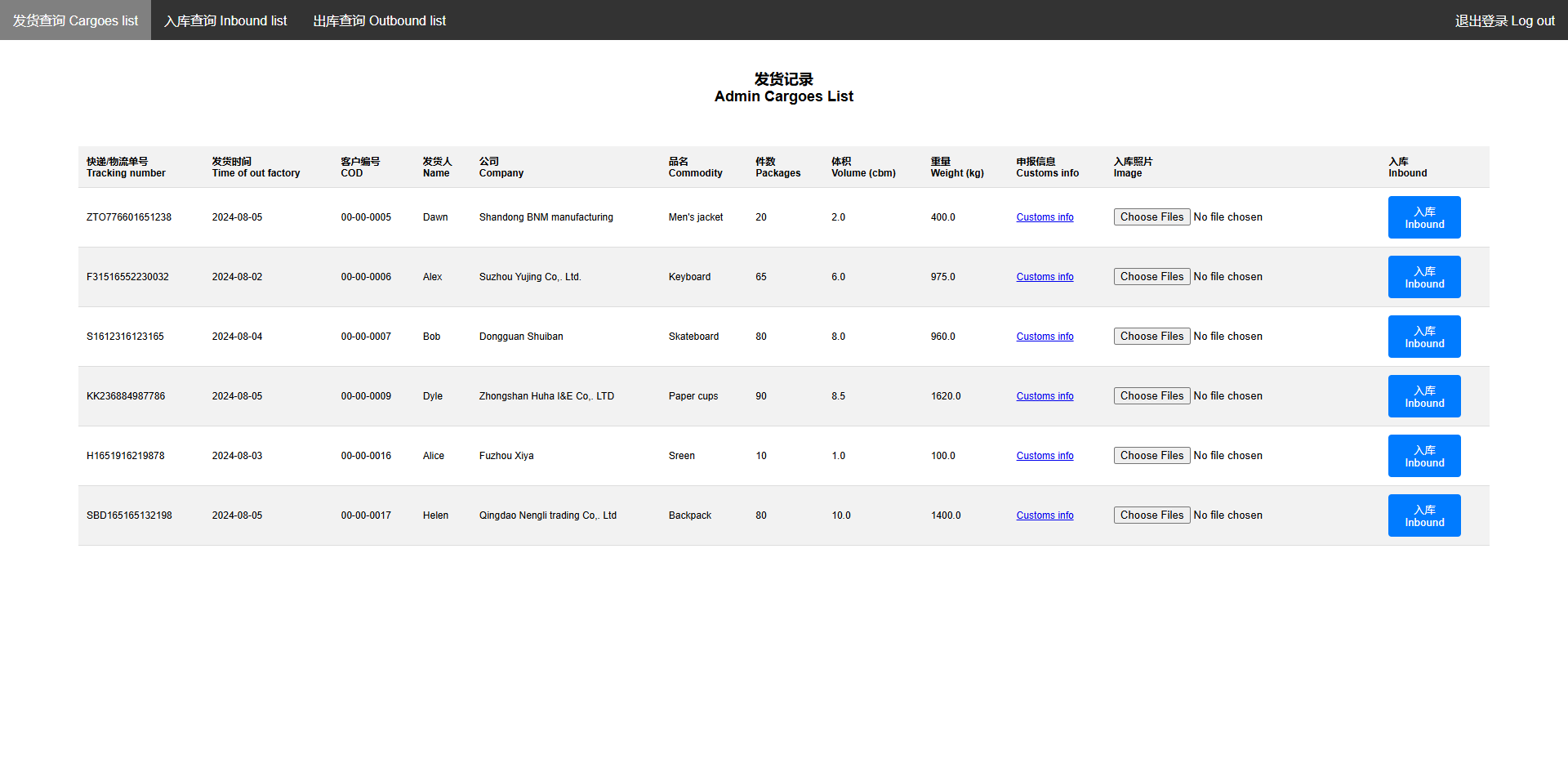

- Admin Login: Warehouse staff can manage all shipping records and oversee warehousing processes.

- Client Login: Client can view all records, including shipping, inbound, and outbound.

-

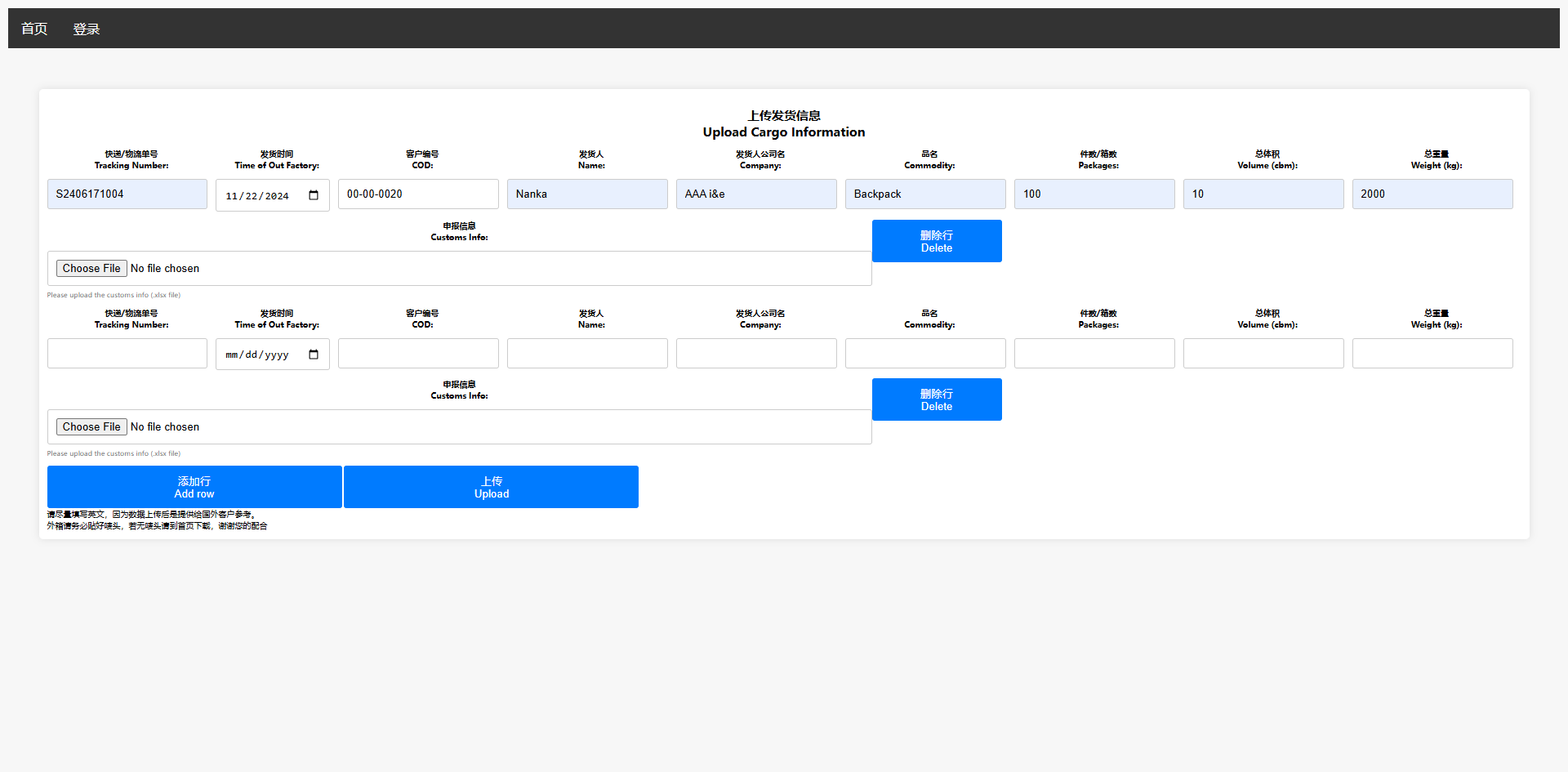

Cargo Details Upload:

Suppliers can upload cargo information to the database, either individually or in bulk when they send goods to warehouse.

-

Inbound Operations:

Warehouse staff can view all on the way to warehouse cargoes, take photos upon arrival and upload, and confirm inbound status with a single click, moving records to the “Inbound Cargoes List.”

-

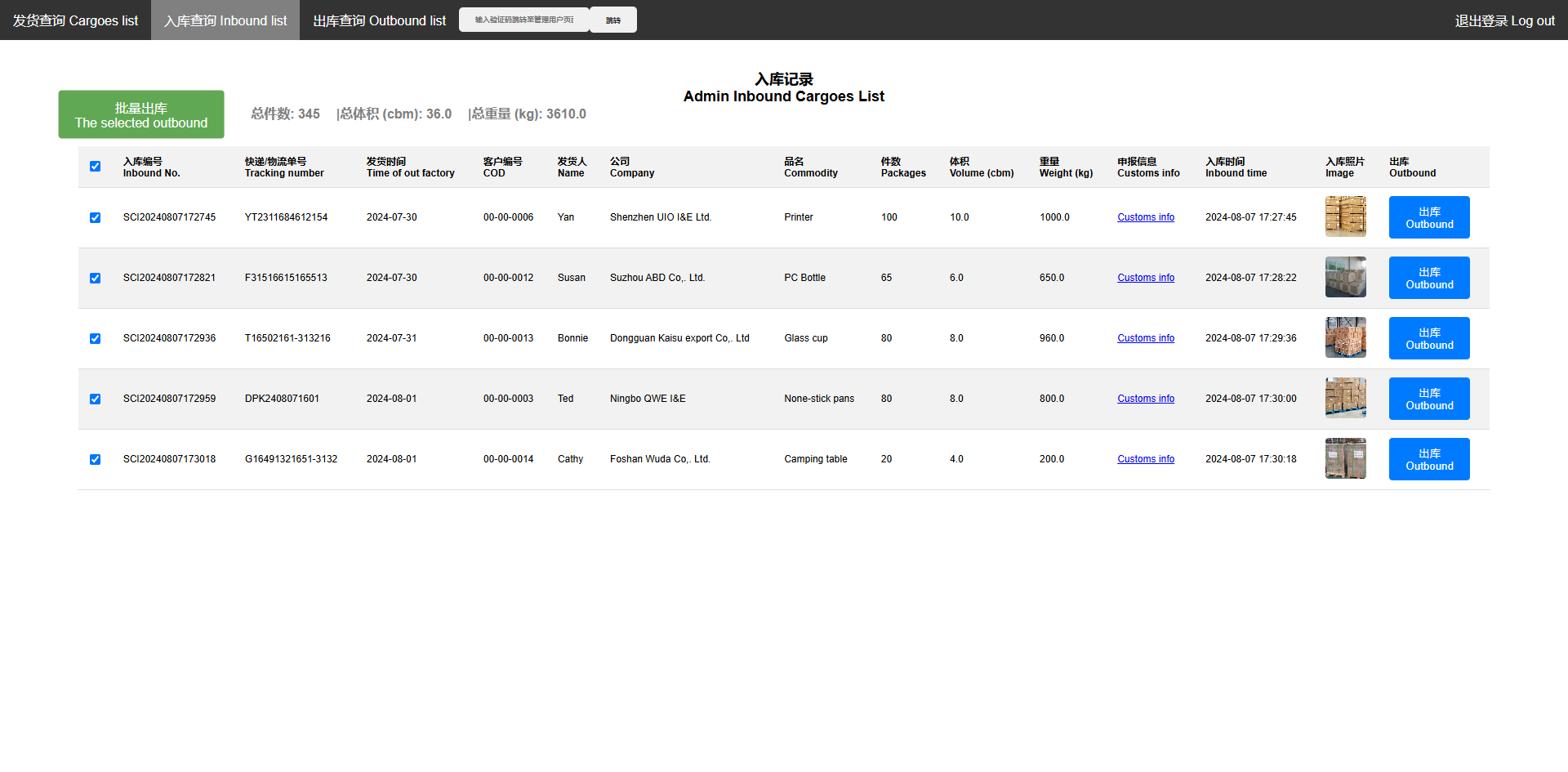

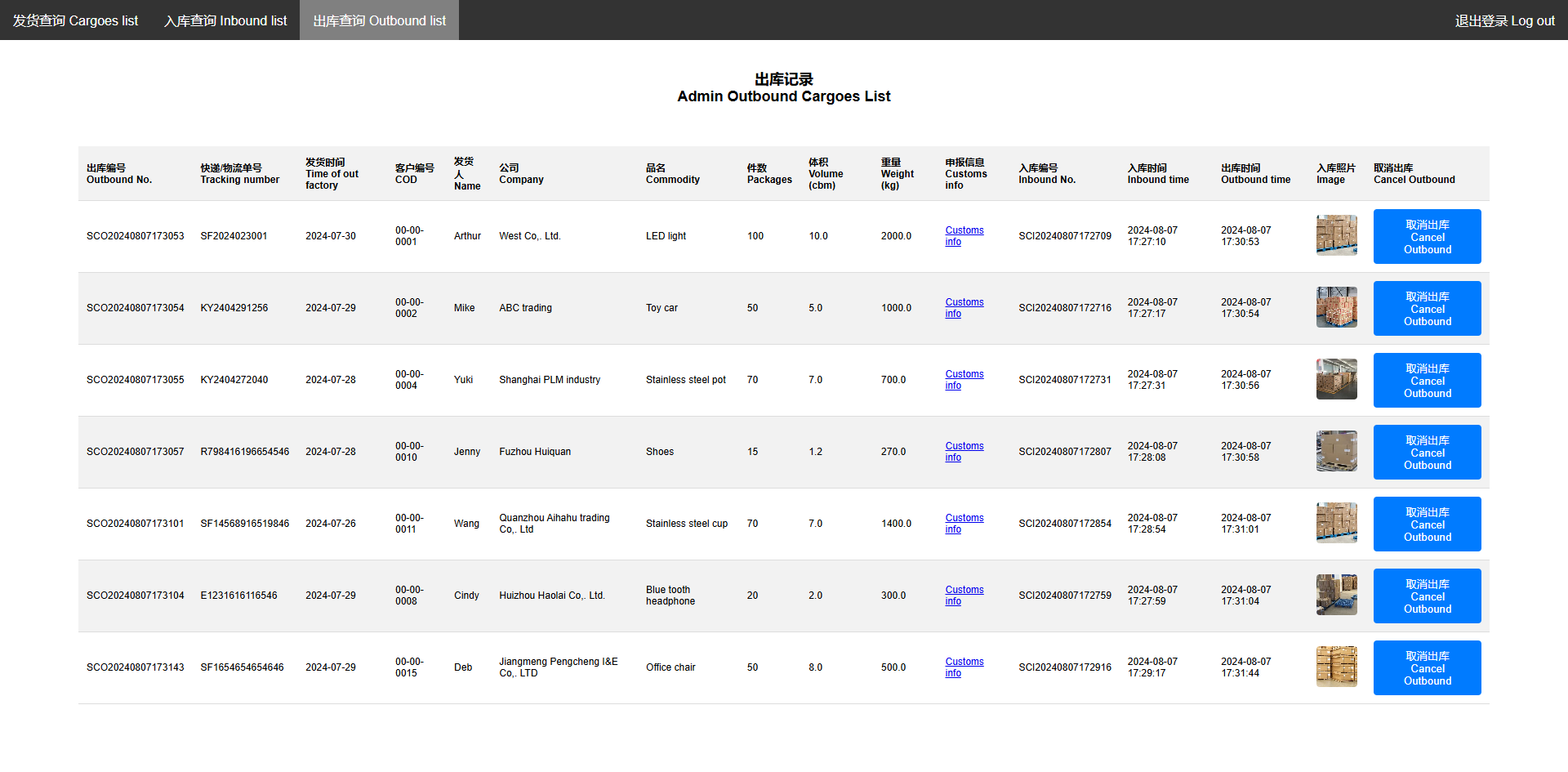

Outbound Operations:

The client can schedule shipments by selecting and moving records to the “Outbound Cargoes List.” Bulk operations are supported.

-

Outbound Correction:

Mistakes can be corrected by moving items back to the “Inbound Cargoes List” with a "Cancel Outbound" button.

-

Language Support:

Admin pages are bilingual (English and Chinese), while client-facing pages are in English only.

Summary

This customized inventory management system empowers our client to efficiently manage and consolidate cargoes, visualize operations, and streamline processes. We are dedicated to providing digital solutions that optimize supply chains with world-class shipping resources, professional expertise, and value-added services.

Contact us today to learn more about how we can support your logistics needs. Your inquiries will receive prompt attention.

Key Benefits for the Client

The customized inventory management system was designed to address the client's growing coordination challenges and cargo volume. After implementation, the client experienced measurable operational improvements:

- Centralized Visibility: All cargo records, whether inbound or outbound, are now visible in one place, eliminating the need for constant back-and-forth with multiple suppliers.

- Reduced Errors: Manual errors in outbound coordination have been minimized with structured, role-based processes and easy correction tools like "Cancel Outbound."

- Improved Supplier Communication: With each factory accessing only its own cargo records, transparency and privacy are maintained while streamlining communication.

- Faster Decision-Making: Real-time updates on cargo status allow quicker response times, efficient scheduling, and more reliable shipping—especially valuable in shipment consolidation scenarios where goods arrive from multiple sources.

Performance Metrics (Before vs After Implementation)

Since launching the system on May 2, 2024, several performance improvements have been observed:

| Metric | Before Implementation | After Implementation |

|---|---|---|

| Monthly cargo batch volume | 40–60 (manual tracking) | 60+ (digitally tracked) |

| Communication loops per shipment | 4–5 (client to factory to warehouse) | 1–2 (client via system interface) |

| Inbound confirmation time | 6–12 hours (via email or calls) | Within 1 hour (via portal upload) |

| Outbound correction handling time | Up to 1 day | Real-time (via "Cancel Outbound") |

| Supplier errors/misuploads | Frequent | Rare (restricted interface access) |

To further streamline planning, many users now integrate a container loading calculator to maximize utilization and reduce dead space in consolidated shipments.

Data Privacy & Access Control

Maintaining strict data privacy was a foundational element in the system's development. The platform uses role-based access to ensure data integrity:

- Factories/Suppliers can only access their own cargo uploads. They cannot see or interact with data from other suppliers, ensuring full confidentiality.

- Warehouse Staff have administrative access to all cargo movements, from arrival to outbound, with permission to upload photos and update statuses.

- Clients can monitor all warehouse activity in real time, including cargo uploads, shipment schedules, and outbound operations, but cannot alter supplier data.

Additionally, all records are optimized for reference during less than container load shipping operations, where batch-level cargo data becomes essential.

Global Logistics Integration

This customized system is not a standalone tool—it's part of our broader vision to offer integrated logistics solutions. It enables seamless collaboration between international factories, clients, and our warehouse team:

- Supports Cargo Consolidation: Ideal for clients sourcing from multiple Chinese factories and needing to consolidate shipments efficiently.

- Facilitates International Shipping: Directly supports outbound preparation for global destinations, aligning with ocean freight, air freight, or multimodal transport.

- Compatible with Existing Operations: The system works in tandem with our warehousing, customs, and shipping processes, creating a single operational ecosystem.

Its compatibility with broader sea freight FCL workflows further supports international customers who rely on partial container shipments to manage costs and flexibility.

Frequently Asked Questions (FAQs)

- Can multiple users from one factory access the system?

Yes, multiple user logins can be created under one supplier profile, allowing operational staff and supervisors to manage cargo entries collaboratively. - Is the system mobile-friendly?

Currently, the system is optimized for desktop use, but a mobile-responsive version is under consideration based on client feedback. - Can this system be adapted for other clients?

Yes, while this version was customized for a specific client, the underlying framework is flexible and can be tailored to fit other business models or countries. - How is data stored and backed up?

All data is stored securely on encrypted cloud servers with daily automated backups, ensuring minimal risk of loss or corruption. - Does the system support other languages?

Yes. Our digital support is fullly customerized no matter what languages customer request, allowing for easy international adoption.